The Henry Guarantee

We are confident that you’ll enjoy and be proud to own any of our Henry firearms, well known for their reliability, accuracy, handsome looks and smooth action.

Our goal has and always will be to manufacture a line of classic, well-crafted firearms that every enthusiast would find readily affordable.

We take great pride in manufacturing our shotguns in the United States, hence our corporate motto “Made in America, or Not Made at All”.

Thank you very much for spending your hard earned money to purchase a Henry. I certainly appreciate it and welcome you to the Henry family. As an owner of a Henry, you are backed by our lifetime warranty and my personal guarantee for 100% satisfaction. I will do what it takes to make certain you are happy with your purchase.

Sincerely,

Anthony Imperato

Henry Repeating Arms

Telephone: 201.858.4400

Simple Limited Lifetime Warranty

It is our promise to you that as long as you own your Henry firearm, it will be free from defects in material and workmanship from the manufacturer. If you have a problem with your Henry firearm, we will fix it at no charge to you. Henry Repeating Arms shall repair, send replacement parts or replace the firearm with a valid warranty claim. If a complete replacement is necessary, the original firearm will not be returned. Henry RAC will provide repairs or replacement at no charge, but will not offer cash, credit, or refund.

WE RESERVE THE RIGHT TO REFUSE SERVICE ON FIREARMS THAT HAVE BEEN ALTERED, ADDED TO, OR SUBSTANTIALLY CHANGED.

Removal of metal from the barrel, or modifications of the firing mechanism and/or operating parts, may lead to a refusal of service on such firearms. There will be a charge for parts and labor to return the firearm to original specifications.

DO NOT, UNDER ANY CIRCUMSTANCES, ALTER THE TRIGGER, “SAFETY” OR OTHER PARTS OF FIRING MECHANISM OF THIS OR ANY OTHER FIREARM. FAILURE TO OBEY THIS WARNING MAY RESULT IN INJURY OR DEATH.

NOTICE: Henry RAC shall not be responsible for injury, death, or damage to property resulting from either intentional or accidental discharge of this firearm, or from its function when used for purposes or subjected to treatment for which it is not designed.

Whether or not you are experienced in the safe handling of firearms, we urge you to read this entire instruction manual carefully. You must follow the safety instructions for your safety and the safety of others. Should you have any questions concerning the instructions in this manual, please call us at 201-858-4400.

WARNING: If you have little or no experience in the safe handling and operation of a firearm, we strongly urge you to take a firearms safety course from an NRA Certified Instructor or someone with equivalent qualifications before using this or any other firearm. You can contact the NRA Firearms Education and Safety Division at 703-267-1470 for the name of an instructor in your area, or contact your firearms dealer, law enforcement agency or local sportsman’s club for training.

General Gun Safety Handling

Apply the following safety rules in every situation, with any kind of firearm:

ALWAYS TREAT EVERY FIREARM AS IF IT IS LOADED AND WILL FIRE. Do not take anyone’s word that the firearm is unloaded – always check for yourself. Never pass your firearm to another person until the cylinder or action is open and you visually check that it is unloaded. Keep your firearm unloaded and safely stored when not in use.

ALWAYS BE SURE OF YOUR TARGET AND WHAT IS BEYOND. A bullet could travel through or past your target for up to 1½ miles. Always be sure your backstop is adequate to stop and contain bullets before beginning target practice so that you do not hit anything outside the range shooting area. If in doubt, don’t shoot! Do not fire randomly into the sky.

NEVER SHOOT ACROSS A HIGHWAY OR ANOTHER ROADWAY.

ALWAYS POINT YOUR FIREARM IN A SAFE DIRECTION. NEVER point a firearm at anyone or anything you do not intend to shoot whether or not it is loaded. This is particularly important when loading, unloading, or field stripping the firearm. ALWAYS control the direction of the firearm; if it fires accidentally, injury, death, or damage to property can be avoided.

NEVER PLACE YOUR FINGER INSIDE THE TRIGGER GUARD OR ON THE TRIGGER UNLESS YOU INTEND TO FIRE. You should also take care to ensure that other objects do not touch the trigger.

NEVER USE ALCOHOL OR DRUGS BEFORE OR WHILE SHOOTING. Your vision, motor skills and judgment could be dangerously impaired, making your gun handling unsafe to you and to others. Further, do not use your firearm if you are on any medication which impairs, even slightly, your mental or physical ability.

ALWAYS SEEK A DOCTOR’S ADVICE IF YOU ARE TAKING MEDICATION. Be sure you are fit to shoot and handle your firearm safely.

NEVER SHOOT AT A HARD SURFACE SUCH AS A ROCK OR A LIQUID SURFACE SUCH AS WATER. A bullet may ricochet and travel in any direction to strike you or an object you cannot see, causing injury, death or damage to property.

NEVER DISCHARGE A FIREARM NEAR FLAMMABLE MATERIAL. Flame and sparks erupt from the firearm when discharged. They could start a fire or cause flammable liquids to explode.

ALWAYS BE AWARE OF POSSIBLE RISK FROM DROPPING YOUR FIREARM. Some parts of the mechanism could be damaged. You may not see the damage, but it could be severe. The firearm may discharge and cause injury, death, or damage to property. If your firearm has been dropped, have it examined by a competent gunsmith before using it again.

ALWAYS KEEP AND CARRY YOUR FIREARM EMPTY WITH THE HAMMER IN THE “SAFE” POSITION except when you intend to shoot, so that your firearm cannot be fired when you do not intend to fire it.

NEVER CROSS OBSTACLES SUCH AS FENCES OR STREAMS WITH A LOADED FIREARM. Always make certain your firearm is unloaded before crossing a fence, climbing a tree, jumping a ditch or approaching other obstacles.

NEVER TRANSPORT A LOADED FIREARM. Keep all firearms unloaded during transport, even when stored in a holster, gun case, scabbard or other container.

NEVER WALK, CLIMB, OR FOLLOW A COMPANION WITH YOUR FIREARM COCKED AND READY TO FIRE. When hunting, hold your firearm so that you can always control the direction of the muzzle.

NEVER LEAVE A LOADED FIREARM UNATTENDED. Someone, especially a child, may fire it and cause injury, death, or damage to property.

ALWAYS INSTRUCT CHILDREN AND NON SHOOTERS TO RESPECT FIREARMS. If you teach your children to shoot or get them trained by a qualified instructor, be certain they know how to use the firearm properly and always supervise them closely. Always stress safety so that your children or others will not fire a rifle when or where it is unsafe to do so.

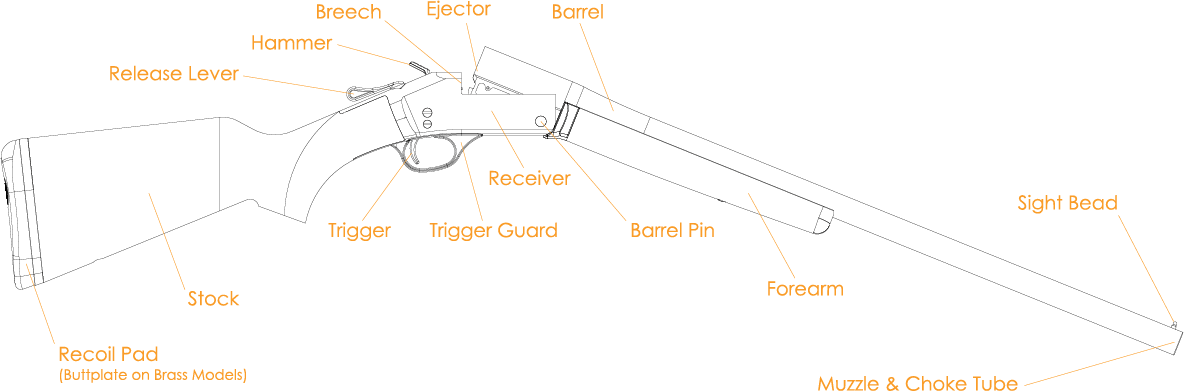

Terminology & Descriptions

Congratulations on your purchase of your new break action Henry 20, 12 Gauge, 12S Slug or .410 Single Shot Shotgun. Whether you purchased the brass, steel or camo option, they all feature the same rebounding external hammer and dual-direction pivoting locking lever setup that blocks hammer contact with the firing pin unless the trigger is pulled. The same interlock system prevents opening the action with the hammer cocked or closing it with the hammer cocked, as additional safety measures.

The stock and forearm is American Walnut with a solid black rubber recoil pad on the steel-framed guns, and a smooth brass buttplate on the brightly polished brass-framed models. Barrels on the H015 and H015B are black finished and the H015T sports a camo barrel. The steel and camo shotguns carry a pistol-grip stock wrist and the brass carries a straight English-style wrist.

Brass beads are standard, barrel lengths are 28” in the 12 and 26” in the 20 and 410. The Turkey 24″ barrel and the 12 gauge slug barrel uses fiber optic sights.

Serial Number

The serial number is located on the underside of the receiver. Record this number in this manual for future reference.

Specifications

H015-12S (3″ Shells)

H015-20 (3″ Shells)

H015-410 (3″ Shells)

H015B-12 (3 1/2″ Shells)

H015B-20 (3″ Shells)

H015B-410 (3″ Shells)

H015Y-20 (3″ shells)

H015T-12 (3 1/2″ Shells)

H015-20/H015B-20 – 26″

H015-410/H015B-410 – 26″

H015Y-20 – 26″

H015T-12/H015-12S – 24″

H015T – Round Camo

26″ Smooth Mod/Rem Style Choke

H015-410/H015B-410 –

26″ Smooth Full Invector Style Choke

H015T-12 – 24″ Turkey Choke

H015-12S – 1:35 ROT

H015-20/H015B-20 – 41.5″

H015-410/H015B-410- 41.5″

H015Y-20 – 40.5″

H015T-12/H015-12S – 39.5″

H015B-12 – 6.83 lbs

H015-20 – 6.62 lbs

H015B-20 – 6.80 lbs

H015-410 – 6.55 lbs

H015B-410 – 6.73 lbs

H015Y-20 – 6.74 lbs

H012T-12 – 6.78lbs

H015B-12/20/410 – Polished Brass

H15T-12 – Camo

H015T-12/H015-12S – Fiber Optic

H015T-12/H015-12S – Fiber Optic

H015B-12/20/410- American Walnut Straight Grip

H015T-12 Camo Pistol Grip

H015B-12/20/410 – Brass

Ammunition

The Henry Single Shot Shotgun 12, 20 Gauge and .410 Bore is chambered for use of shotgun shells listed below only. Use of any other ammunition can cause excess pressure and possible serious injury.

The gauge of your new H015 is inscribed on the barrel near the receiver.

– Factory shotgun shells only.

– 12 gauge – 3 1/2″ Shotgun Shells – Smooth Mod/Rem Style Choke

The H015T uses a Turkey Choke.

– 12 gauge slug barrel – 3″ Slug Shells – 1:35 ROT

– 20 gauge – 3″ Shotgun Shells – Smooth Mod/Rem Style Choke

– .410 bore – 3″ Shotgun Shells – Smooth Full Invector Style Choke

– Never attempt to load different size shells.

– A cylinder choke is recommended for shooting rifled slugs in a smooth-bore barrel.

Sabot slugs should only be shot through fully-rifled slug barrels.

ALWAYS HAVE ADEQUATE VENTILATION IN THE AREA THAT YOU DISCHARGE A FIREARM. LEAD EXPOSURE CAN OCCUR FROM DISCHARGING FIREARMS IN POORLY VENTILATED AREAS, CLEANING FIREARMS OR HANDLING AMMUNITION.

Lead is a substance that has been known to cause birth defects, reproductive harm and other serious injury. Wash hands thoroughly after exposure.

Ammunition Selection

ALWAYS USE THE CORRECT AMMUNITION FOR YOUR PARTICULAR FIREARM.

Henry Repeating Arms Firearms are designed to function with a variety of brands and types of factory-manufactured ammunition in the appropriate caliber, but not all ammunition produces the same result. Be sure the only ammunition you carry correctly matches what you are shooting. Never use non-standard, reloaded, or “hand-loaded” ammunition which has not been subjected to internal ballistic pressure testing.

Henry RAC recommends that after you read and understand this manual, you go to the range and fire different ammunition which is appropriate to the caliber of your firearm. Once you find the ammunition which functions best, keep using it.

Range and Shooting Cautions

ALWAYS DESIGNATE A KNOWLEDGEABLE AND RESPONSIBLE PERSON TO BE IN CHARGE TO MAINTAIN SAFETY CONTROL WHEN A GROUP IS FIRING ON A RANGE. Obey their commands so that discipline is maintained to reduce the possibility of accidents.

ALWAYS CARRY YOUR FIREARM EMPTY WITH THE ACTION OPEN WHILE ON A RANGE until preparing to fire and keep it pointing towards the backstop when loading, firing, and unloading to eliminate the risk of injury, death or damage to property.

ALWAYS KEEP THE HAMMER IN THE uncocked POSITION UNTIL YOU ARE READY TO FIRE. This will minimize the risk of an accidental discharge.

ALWAYS WEAR EYE AND EAR PROTECTION SPECIFIED FOR USE WITH FIREARMS. Flying particles could damage eyes and cause blindness. Without ear protection, the noise of even one shot from your rifle and from other guns close to you could leave a “ringing” in the ears for some time after firing and the cumulative long term effect could be permanent hearing loss. Make sure others in the vicinity of where you are shooting are doing so as well.

ALWAYS KEEP CLEAR AND KEEP OTHERS CLEAR OF THE EJECTION PORT. Spent shells are ejected with enough force to cause injury. The ejection port must also be unobstructed by your hand to insure safe ejection of spent rounds. Never place fingers in ejection port – they could be burned by hot metal or injured by the bolt moving forward.

NEVER PUT YOUR FINGER INSIDE THE TRIGGER GUARD UNTIL YOU ARE AIMING AT A TARGET AND READY TO SHOOT. This will prevent you from firing the firearm when it is pointing in an unsafe direction.

NEVER JOKE AROUND OR ENGAGE IN “HORSEPLAY” WHILE HANDLING YOUR FIREARM. Doing so could cause an accidental discharge.

Operating Instructions

Rebounding Hammer Safety

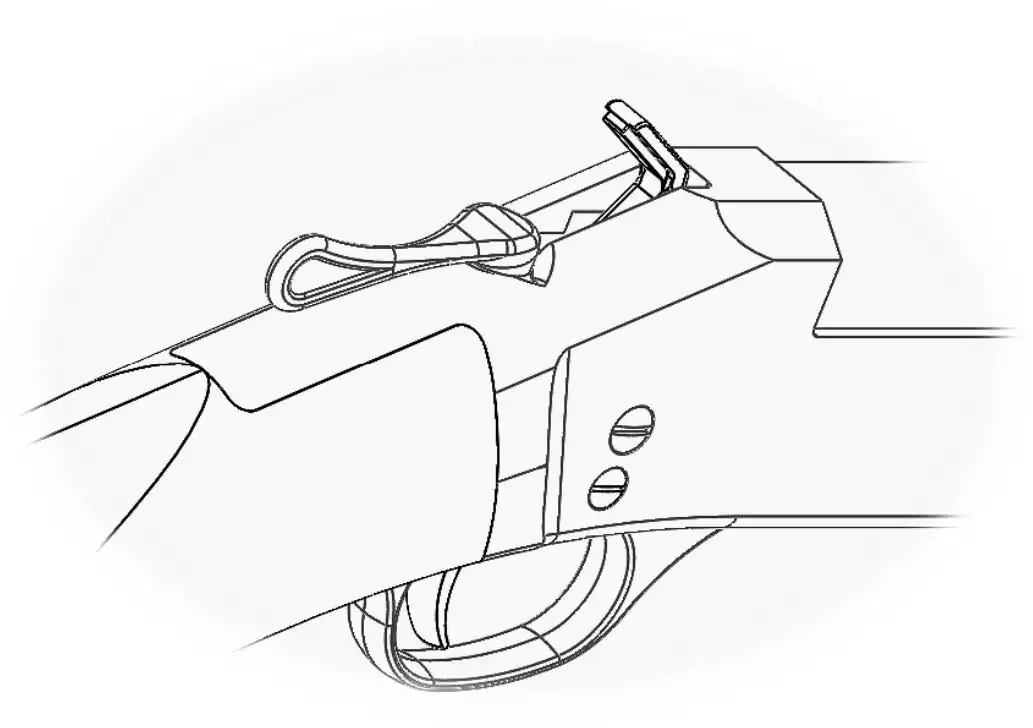

The action has no external manual safety; it uses a rebounding hammer that cannot touch the firing pin unless the trigger is deliberately pulled, and an interlock system that does not allow the action to open if the hammer is cocked. The barrel will also not close if the hammer’s cocked while it is open. Safe to carry, and simple to operate.

To return the hammer back to the safe position from the fire position: Keep your thumb on the hammer as you pull the trigger. As soon as you feel the hammer exerting forward pressure against your thumb, remove your finger from the trigger and ease the hammer slowly forward to the Rebound/Safety position.

If you do not have a full understanding of how the safety system works, please call us immediately at 201-858-4400 and ask for technical assistance.

Maintenance Before Use

Before using your firearm for the first time, it should be cleaned. (See the cleaning instructions.) Your firearm was treated at the factory with either a preservative or oil to protect it against corrosion during shipping and storage. Preservative and oil should be wiped from the bore, chamber and exposed areas using a clean swab or patch before using the firearm.

Purchase cleaning supplies that are specifically designated for your type and caliber of firearm. Many suppliers offer these in kit form for your convenience. Follow the instructions provided with your cleaning supplies. Whenever your firearm has been exposed to sand, dust, extreme humidity, water or other adverse conditions, it should be cleaned and lubricated.

How to Load

Prior to loading your shotgun, make certain to point the muzzle in a safe direction.

Clear the firearm of any cartridges prior to loading. Make certain that the barrel, receiver and chamber are free from any obstruction. Make sure to select the correct ammunition for your shotgun. The gauge is listed on the barrel.

Be sure the hammer on your firearm is not cocked. Henry’s interlock system does not allow the action to open or close if the hammer is cocked.

Your break-action firearm uses a locking release lever on top of the frame, behind the external hammer spur to break open for loading and unloading. This lever can be pivoted left or right from its center position to unlock, which works well for both right and left-handing. The barrel will break open, exposing the breech so you can load and unload the weapon. Once loaded, swing the barrel back into place. Your firearm is now loaded.

THE CAPACITY IS 1 ROUND.

How to Shoot

If you want to fire the gun, bring the hammer back to the cocked position, aim in a safe direction at your target, and pull the trigger.

How to Unload

As with loading, be sure the hammer on your firearm is not cocked. Henry’s interlock system does not allow the action to open if the hammer is cocked. The H015 single shot shotgun fully ejects the shotgun shell/hull after firing.

Chokes

12 and 20 Gauge Your Henry 12 or 20 Gauge Shotgun comes with a Smooth Mod/Rem style choke. Your 12 Gauge H015T comes with a Turkey choke.

.410 Bore Your Henry .410 Shotgun comes with a Smooth Full Invector style choke.

Make sure to check choke tightness periodically to ensure that it has not become loose. Additional Invector chokes can be purchased from your local gun shop.

Changing the Choke

Make sure to inspect chokes for damage before installation as a damaged choke may damage your shotgun and/or cause serious personal injury.

Before removing or installing and choke tube, open the action and verify that firearm is not loaded.

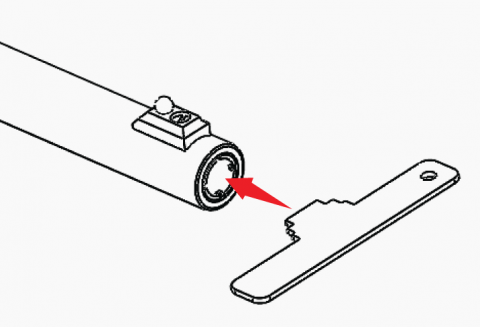

REMOVAL OF CHOKE TUBES

1. To change or remove the choke tubes, use the wrench that was supplied.

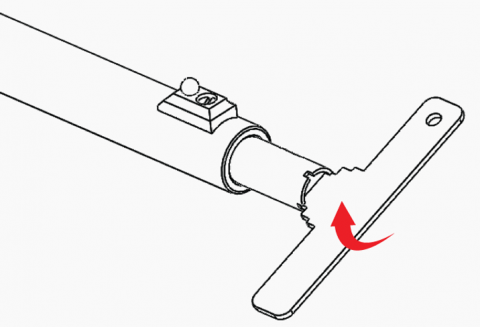

2. Align either stepped end of the tool with the notches in the choke tube as shown. Turn counter clockwise.

3. When the choke tube is loosened, remove it completely with your fingers. Place the choke tube on a clean, dry surface.

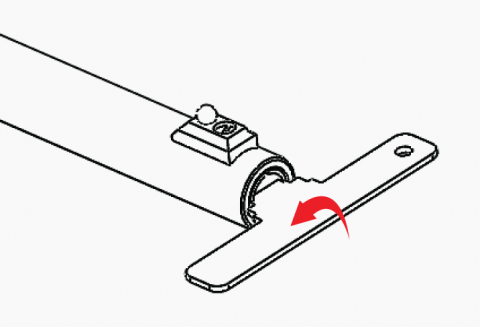

1. To change or remove the choke tubes, use the supplied tool.

2. Align stepped end of the tool with the notches in the choke tube as shown above. Turn counter-clockwise.

3. Start new choke tube into the muzzle with the threaded end entering the barrel first and the 4 notches pointing away from the barrel.

4. Turn clockwise, starting threads by hand, then use supplied tool to fully tighten.

INSTALLING A NEW CHOKE TUBE

1. Start the new choke tube into the muzzle with the threaded end entering the barrel first and the 4 notches pointing away from the barrel.

2. Turn clockwise, starting threads by hand.

3. Use supplied tool to tighten.

The end of the choke tube will be flush with the end of the barrel when properly installed. Do not use excessive force when installing. Choke tube tightness should be checked periodically to avoid damage to the choke, firearm, and to prevent injury to you or those around you.

NEVER FIRE YOUR SHOTGUN WITHOUT A CHOKE IN PLACE. FIRING WITHOUT A CHOKE CAN DAMAGE THE THREADS FOR THE CHOKE.

Inspect choke tubes periodically to insure they are properly installed and in good condition. Pay special attention to the threaded end of the choke tube to be certain it is not deformed or dented. Never fire this firearm without a choke tube properly installed. Failure to do so will damage the precision threads on the inside of the barrel. Firing this firearm with loose choke tubes may lead to damage to the choke tube and barrel, as well as serious personal injury to you or those around you.

Sights and Sight Adjustments

(FOR H015-12 Slug Barrel and Turkey Shotgun)

Your shotgun is equipped with a Fully Adjustable Fiber Optic rear sight. The rear sight is adjustable for elevation (shooting high and low) and for windage (shooting left and right).

Your Henry shotgun is equipped with a Fiber Optic Bead Front Sight.

Malfunction and Troubleshooting

FAILURE TO FIRE. A misfire occurs when the firing pin strikes the primer and it does not fire. IF THE FIREARM FAILS TO FIRE DO NOT PUT IT DOWN OR OPEN THE ACTION. ALWAYS HOLD THE FIREARM, KEEPING IT POINTED IN A SAFE DIRECTION AND WAIT 30 SECONDS. IF A HANGFIRE (SLOW IGNITION) HAS OCCURRED, THE ROUND MAY FIRE WITHIN 30 SECONDS.

If the round does not fire, open the action, eject the round and examine the shell. If the firing pin indent on the primer is light or non-existent, have the firearm examined by a competent gunsmith before firing again. If the firing pin indent on the rim appears normal (in comparison with similar previously fired rounds) assume you have faulty ammunition. Segregate the misfired round from other live ammunition and empty cases, reload, and carry on firing.

Cleaning, Storage and Maintenance

Cleaning Safety Precautions

WARNING: BEFORE PERFORMING CLEANING PROCEDURES, MAKE SURE THE HAMMER IS IN THE FIRED-DOWN POSITION, WHICH ALLOWS YOUR SAFETY TO FUNCTION AS DESIGNED. OPEN THE ACTION AND MAKE CERTAIN YOUR FIREARM IS COMPLETELY UNLOADED. KEEP THE MUZZLE POINTED IN A SAFE DIRECTION. FAILURE TO FOLLOW THESE WARNINGS COULD RESULT IN SERIOUS INJURY OR DEATH.

KEEP ALL AMMUNITION AWAY FROM THE CLEANING AREA. NEVER TEST THE MECHANICAL FUNCTION OF YOUR RIFLE WITH LIVE AMMUNITION. FAILURE TO FOLLOW THESE WARNINGS COULD RESULT IN SERIOUS INJURY OR DEATH.

NOTICE! It is very important that the bore of your rifle be cleaned thoroughly and promptly after shooting. Do not leave discharged (empty) cases in the chambers for any length of time, as the chemical composition of many cartridges contain moisture which can “sweat” out of the shell and onto the chambers’ surfaces, and possibly cause corrosion and rust.

How to Clean

Regular cleaning is important in order for your gun to operate efficiently and safely. Taking proper care of it will also maintain its value and extend its life.

WE SUGGEST THAT YOU USE BIRCHWOOD CASEY GUN SHEATH OR A MILD SOLVENT such as Hoppe’s No. 9, Kleenbore or Breakfree.

NOTICE! DO NOT ATTEMPT TO TAKE YOUR FIREARM APART FURTHER THAN EXPLAINED IN THIS MANUAL. Your firearm is a specialized, finely fitted mechanism. You may permanently damage it by attempting to disassemble the inner mechanisms. If further disassembly for service or cleaning is required, take your firearm to a qualified gunsmith.

ALWAYS CLEAN FROM THE NATURAL DIRECTION OF THE BULLET. When you fire your gun, the powder residue and dirt are in the barrel. The chamber and receiver are clean. If you run a brush or patch from the muzzle end you will push this dirt, residue, and moisture into the chamber and receiver. This is a major cause of stuck cases or problems. If you push or pull a brush back toward the chamber, you will notice the brush will throw the debris from the bore back into the chamber. You do not have to disassemble this rifle in order to clean it sufficiently and to keep it operating properly.

USE A CLEAN PATCH SURFACE EACH TIME YOU GO DOWN THE BARREL. When you are using your firearm you will get abrasive dirt in the muzzle. The patch with solvent will flush this dirt out in the shortest distance. If you use this patch surface again, the dirt will be deposited in the chamber and neck. The next bullet down the barrel picks up this dirt and erodes the throat. This is the exact equivalent of cleaning in the wrong direction.

NEVER GO BACK AND FORTH REVERSING THE BRUSH. This will bend the bristles on the brush. This is the equivalent of bending a wire back and forth until it breaks. You will always ruin a brush if you reverse it while in the bore.

USE ONLY A FEW DROPS OF SOLVENT/LUBRICANT OIL. Use only the amount of solvent that the patch will absorb. If you use too much, the solvent or oil will drip down into the trigger mechanism; this will cause a gummy trigger. If you use too much oil, it will drain back toward the stock and could cause premature failure of the wood.

CENTER THE TOP AND ROD. BE CAREFUL NOT TO LET EITHER RUB THE BORE. All firearms record their history. This is the reason most people look down the barrel of a firearm. An experienced eye can tell the method of cleaning, the number of shots, and the gun maintenance applied to the firearm. Many marks are caused by people who carelessly let the tip or rod rub the inside the barrel.

NEVER RUN A BRUSH IN THE BARREL FIRST. This will damage the firearm. The brush will pick up dirt, moisture or powder residue and deposit it into the chamber or receiver. Never dip a brush in solvent. The solvent at the brush core will collect dirt and drop it into the receiver and chamber. Remember – Rust is neglect. Make sure all exposed metal surfaces are coated with a film of oil. After being subjected to damp weather, thoroughly wipe the bore and metal surfaces. Then apply a new film of oil. If exposed to a soaking rain, snow or salt spray, a more thorough cleaning and oiling may be necessary. Wipe the bolt clean of any debris with solvent and a patch or small rag. Spray the bolt with some gun oil. A gun brought out of prolonged storage should also be cleaned before shooting. Accumulated moisture and dirt, or solidified grease and oil, can prevent the gun from operating properly. We recommend the use of pull through cleaning kits or cleaning with a rod type kit. Overtime, depending on the amount of use and how it is stored, we do recommend that you take your Henry to a gunsmith to have it inspected at which time it can also be cleaned more thoroughly.

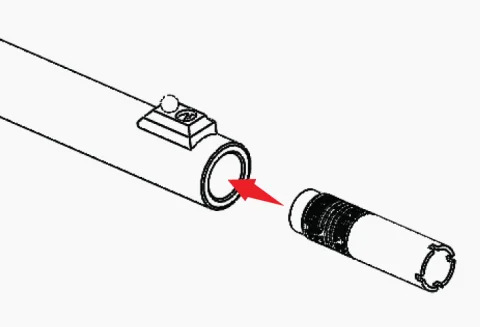

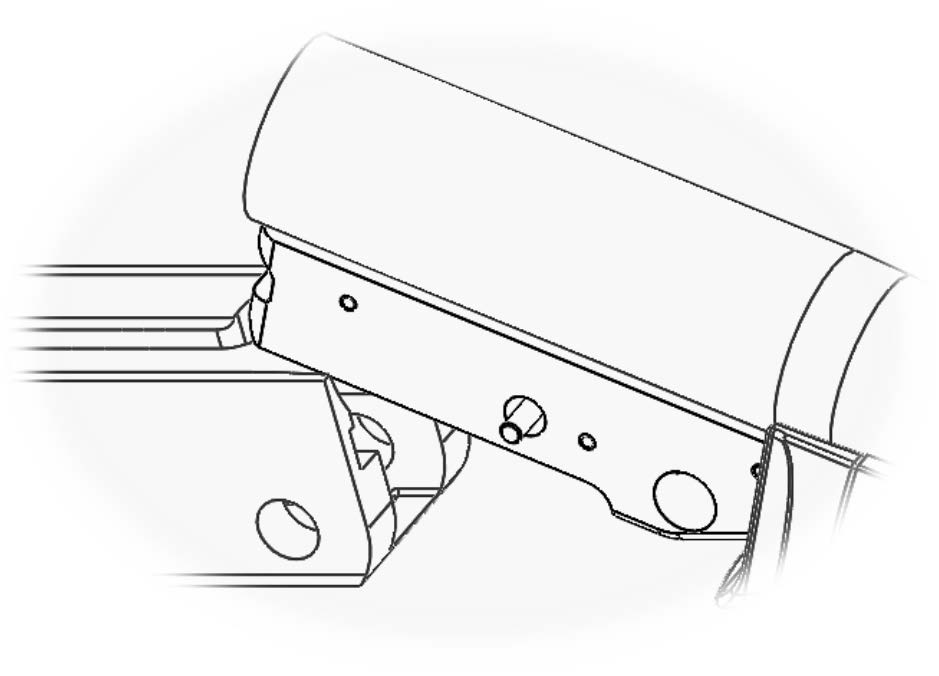

Field Stripping

Be sure your Single Shot is unloaded. Remove the barrel pivot pin by tapping it out (in either direction). Remove the barrel from the frame. To reassemble, reverse these steps, making sure that you check for proper functioning of the hammer/trigger mechanism prior to loading and firing.

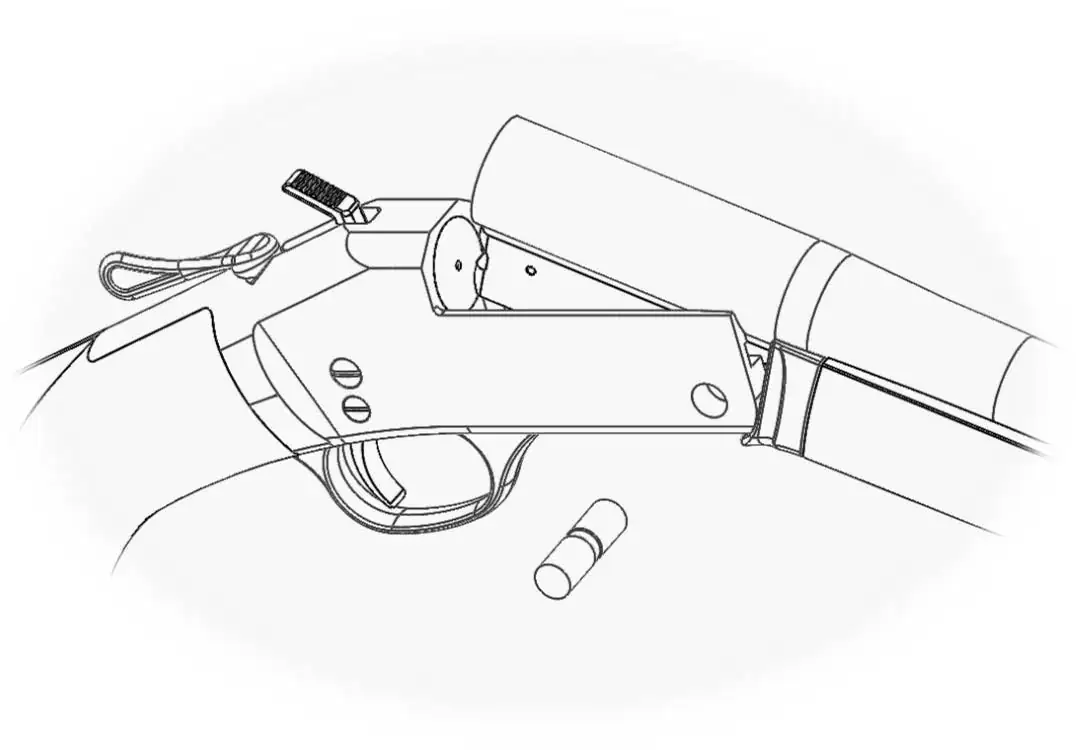

1) With the hammer in the resting position, open the action to verify that the chamber is empty.

2) Remove the pivot pin by tapping it out with a 3/8″ diameter or smaller wooden, brass, or plastic dowel or rod. This can be done from either direction.

3) Remove the barrel assembly from the receiver assembly. The ejector/extractor release pin needs to pass cleanly through the slots in either side of the receiver. To reassemble, reverse these steps, making sure that you check for proper functioning of the action, hammer, and trigger mechanisms prior to loading and firing.

Maintenance Before Storage

When storing your firearm, do not encase it in anything that will attract or hold moisture, for example, leather or heavy cloth. Also, do not store firearms with a plug inserted in the barrel because this can be a contributing factor to moisture accumulation.

If your firearm is to be stored for an extended period, the bore, chamber and internal surfaces should be oiled with a high-quality lubricating oil or preservative intended for firearms. The external parts; receiver, bolt and barrel should be coated with an anti-rust oil.

Before using your firearm again, be sure to clean it. Every time you clean your firearm, check it for signs of wear. If wear is noted, do not use the firearm, have it checked by a qualified gunsmith.

Make sure your firearm is in good mechanical condition before firing it. Periodically have your firearm checked for signs of erosion, cracking, or wear by the factory or a factory certified gunsmith.

Storage Safety and Precautions

NEVER LOCK A LOADED FIREARM AND NEVER LOAD A LOCKED FIREARM!

ALWAYS CHECK TO MAKE SURE YOUR FIREARM IS NOT LOADED BEFORE CLEANING, STORING, TRANSPORTING IT, LAYING IT DOWN, OR HANDING IT TO ANOTHER PERSON so that it cannot be fired when it is unsafe to do so.

ALWAYS KEEP AND STORE YOUR FIREARM AND AMMUNITION IN SEPARATE, LOCKED LOCATIONS, OUT OF REACH AND SIGHT OF CHILDREN AND UNTRAINED PERSONS. Safe and secure storage of your firearm and ammunition are your responsibility.

NEVER LEAVE THE KEY TO THE LOCK FOR YOUR FIREARM WITH THE STORED FIREARM!

NEVER ASSUME THAT A “HIDING” PLACE IS A SECURE STORAGE METHOD. Others may be aware of your storage location or come upon it by chance. It is your personal responsibility to use common sense when storing your firearm and ammunition and to always make sure they are not accessible to children or other unauthorized persons.

NOTE: Do not store your firearm in an air-tight container, and do not seal or attempt to seal the barrel to exclude dust, as the internal steel surface is more likely to rust or corrode by doing this.

BEWARE OF BARREL OBSTRUCTIONS. Be sure the barrel is clear of obstructions before shooting. Mud, water, snow or other objects may inadvertently lodge in the barrel bore. A small obstruction can cause a dangerous increase in pressure and may damage your firearm and cause injury to yourself and others.

BEFORE CHECKING FOR A BARREL OBSTRUCTION, BE CERTAIN YOUR FIREARM IS COMPLETELY UNLOADED. After assuring yourself that the firearm is completely unloaded, open the action and look through the barrel to be sure it is clear of obstructions. If an obstruction is seen, no matter how small it may be, clean the bore with a cleaning cord or a patch as described in the CLEANING section of this owner’s manual.

BE SURE ALL ACCESSORIES, SUCH AS SLINGS, SCOPES AND OTHER ACCESSORIES ARE COMPATIBLE WITH YOUR PARTICULAR FIREARM AND THAT THE ACCESSORIES DO NOT INTERFERE WITH ITS SAFE OPERATION.

It is your responsibility to understand and follow all of the instructions in the safety manual that accompanied your firearm, as well as those which may be supplied with your ammunition and any accessory.

NEVER DISASSEMBLE YOUR FIREARM BEYOND THE FIELD STRIPPING PROCEDURE OUTLINED IN THIS MANUAL. Improper disassembly or reassembly of your firearm may be dangerous and can lead to serious injury or death.

NEVER MANIPULATE, ADJUST OR CHANGE ANY OF THE INTERNAL COMPONENTS OF YOUR FIREARM UNLESS SPECIFICALLY INSTRUCTED TO DO SO IN THIS MANUAL. Improper manipulation of any other internal component may affect the safety and reliability of your firearm and may cause serious injury or death.

NEVER ALLOW ANY ALTERATION OR REPLACEMENT OF PARTS IN YOUR FIREARM UNLESS PERFORMED BY A QUALIFIED GUNSMITH USING AUTHORIZED PARTS. If you do otherwise, improper functioning of your firearm may occur and serious injury or death and damage to property may result.

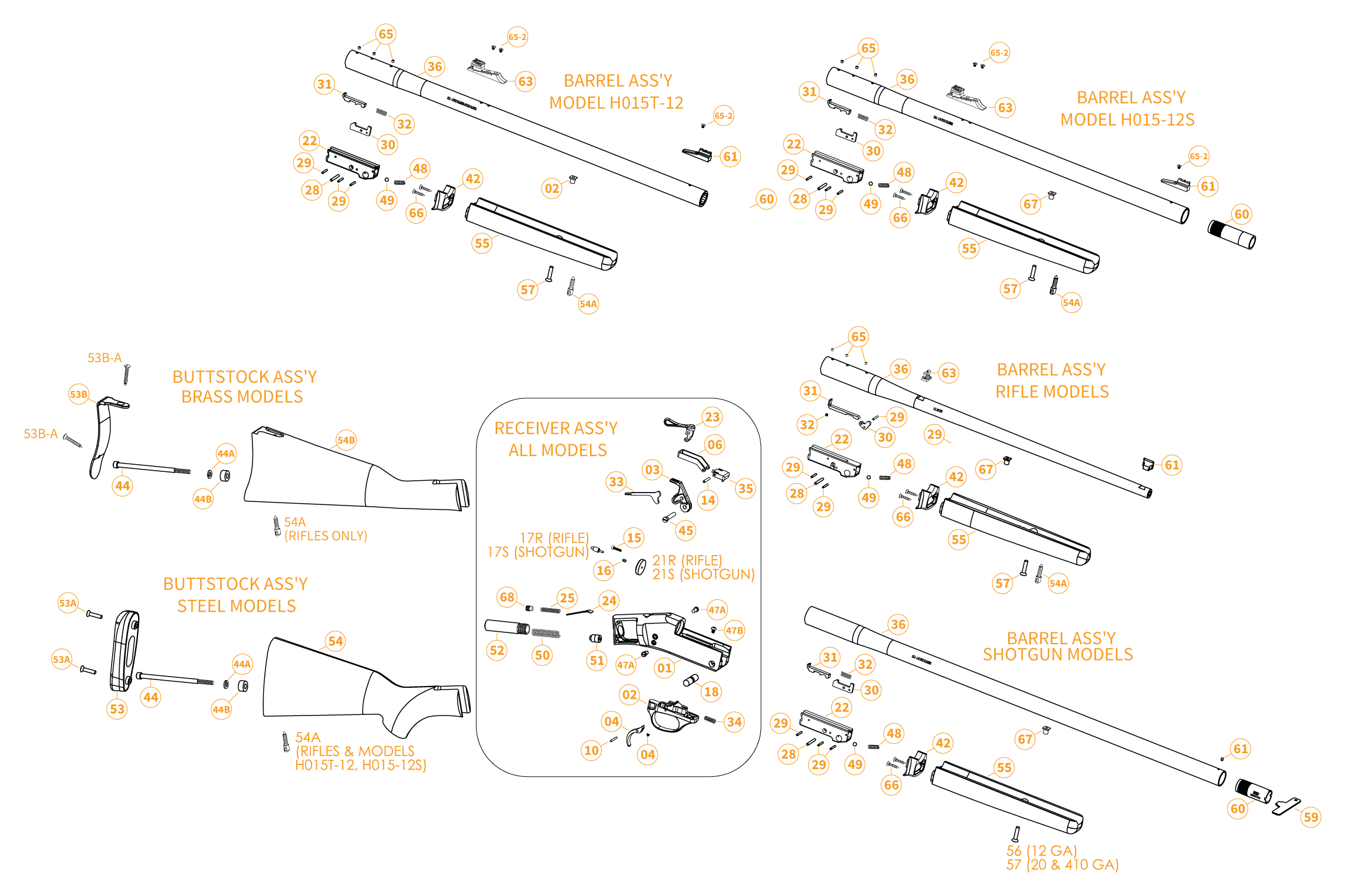

Parts

An illustration and list of part names are included in this manual. Please note that not all parts are available for sale. Those parts which are available should be installed by a licensed gunsmith. When ordering parts, please give part name and part number.

Important: If you make unauthorized adjustments or use unauthorized parts, Henry Repeating Arms Company will not assume responsibility for the proper functioning of the shotgun.

This gun is manufactured to perform properly with the original parts as designed. It is your duty to make sure any parts you buy are installed correctly and that neither replacements nor originals are altered or changed. This is why we say take it to a licensed gunsmith station. Your gun is a complex tool with many parts that must relate correctly to other parts. Putting a gun together wrong or with modified parts can result in a damaged gun, danger, and injury or death to you and others through malfunction. Always let a qualified gunsmith work on your gun and check any work you think was not performed by a gunsmith.

List of Parts

Servicing and Repair

If you believe that your Henry firearm requires repair or adjustment, we suggest that you first contact our Customer Service by visiting the “Contact Us” page on our website, or by phone at 201.858.4400. It may be a problem that we can resolve by phone or by sending a replacement part. For international customers please visit the “Contact Us” page on our website for instructions.

In the unlikely event that your firearm requires adjustments or repair, please make certain that it is unloaded and send it to us at the following address:

HRAC

Att: Repair Dept.

107 W. Coleman Street

Rice Lake, WI 54868

Enclose an explanation of the problem in as much detail as possible.

Make certain to include your complete name, address, phone number and serial number. Make sure your firearm is packaged to prevent it from being damaged. The package should be insured to protect against Loss or Theft.

Do not include “Henry Repeating Arms” in the address on the package, in order to prevent an inquisitive thief from being attracted to it by such information.

You can use the original box for return, however, you should make sure it is wrapped in a brown or other colored paper as to not indicate that the box contains a firearm. This helps to maintain the confidentiality of your rifle to ensure it gets back to us safely.